New system capable of evaluating the rheological properties and structure of soft matter

What is soft matter ?

There are many soft materials called “soft matter” around us.

For example, “polymer materials” such as plastics and rubber, “colloid dispersion-based materials” such as foodstuffs and cosmetics, and “liquid crystals” used in PC and smartphone screens are common soft matter. In recent years, many products have been developed that take advantage of the various characteristics and functionality of soft matter. For example, there are many “spreadable materials” such as hand creams that are easy to apply and remain in place after application. The properties of soft matter that allow for easy application (easily deformable) and the properties that ensure they stay in place (maintain their shape) are essentially contradictory. Therefore, the soft matter that we use casually in our daily lives has a variety of functions to suit its intended use.

Rheometers actively contributing to the development of soft matter

Then, how are various functionalities imparted to soft matter? This is achieved by adeptly controlling the relationship between the stimuli (force) applied to the material and its response (deformation and flow), in other words, by controlling the rheological properties adeptly. To ensure robust control of rheological properties, it is necessary to first evaluate those properties quantitatively.

A rheometer is a measurement device capable of measuring and evaluating various properties of soft matter. With increasing expectations for soft matter across various fields worldwide, there is ongoing advancement in the development of new materials and the enhancement of existing ones through the use of rheometers.

The powerful combination of a high-speed polarization camera and a rheometer!

However, actual development and improvement of materials involve a lot of trial and error. This is because relying solely on evaluations using a rheometer often lacks the necessary information to explain the “mechanisms” behind why certain properties (functions) are obtained.

The “mechanisms” underlying the various properties (functions) of soft matter relate to change in the internal structure of materials. In the example of hand cream mentioned above, under small forces, it forms a structure that the maintains the shape of the material, while under large forces, it changes into a structure that is more flowable. There are various materials for soft matters, and the formed structure and their changes differ significantly depending on the characteristic of the material. Therefore, without understanding the structures and the conditions under which structural changes occur, it is difficult to design and develop materials that can meet required functionalities quickly and efficiently. However, it is not possible to evaluate the structures described above solely based on the rheological property obtained with a rheometer.

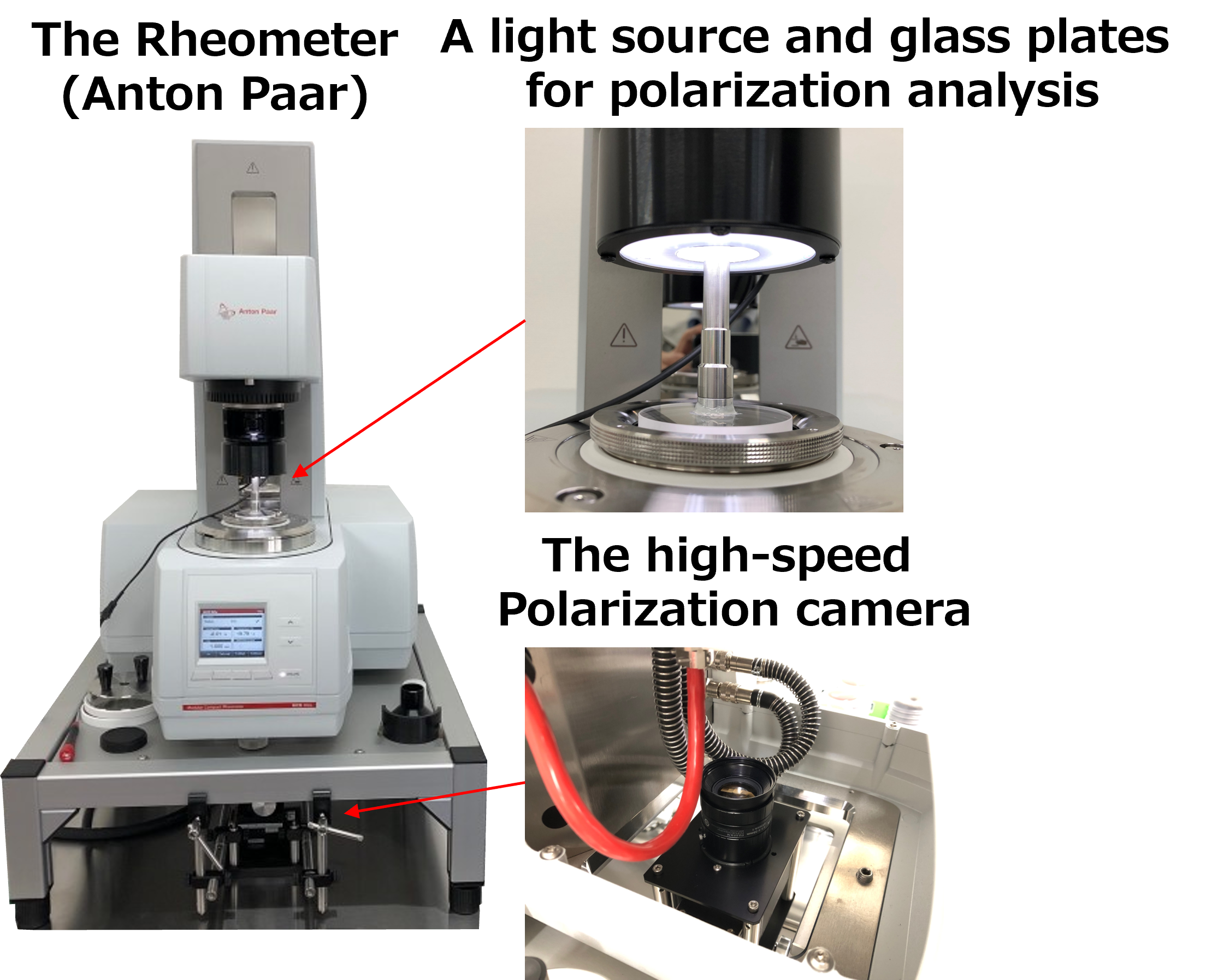

To meet such demands, we have collaborated with Anton Paar Japan K.K. (Website: https://www.anton-paar.com/jp-jp/) to develop a novel measurement system that combines a rheometer with a high-speed polarization camera.

With this system, it becomes possible to measure various rheological properties using a rheometer and evaluate structural changes using a high-speed polarization camera simultaneously. Consequently, it can make a significant contribution to the development of new materials across various fields and the optimization of materials for specific applications.

A case study

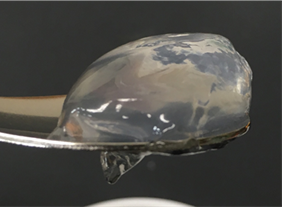

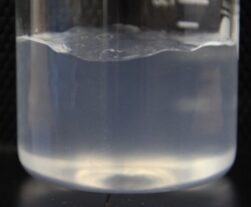

In this section, we introduce a case study of measuring cellulose nanofiber (CNF) suspensions, which exhibit properties similar to “spreadable materials”. CNF is an eco-friendly natural material with attributes such as being lightweight, possessing high strength, having a low thermal expansion coefficient, and high-water absorption. It is expected to be used in various fields, including rheology modifiers, composite materials, thermal insulators, and optical and electronic devices. Particularly for applications in rheology modifiers and composite materials, understanding the rheological properties of CNF (such as viscosity and elasticity) is essential. Although various characteristics of its rheological properties have been reported, the reasons for such behavior ― specifically, the structure of the material in which CNF is dispersed and its changes ― remain unknown.

A sample of TEMPO-oxidized cellulose nanofibers dispersed in water.

(This sample was prepared using a sample provided by DKS Co., Ltd., Japan)

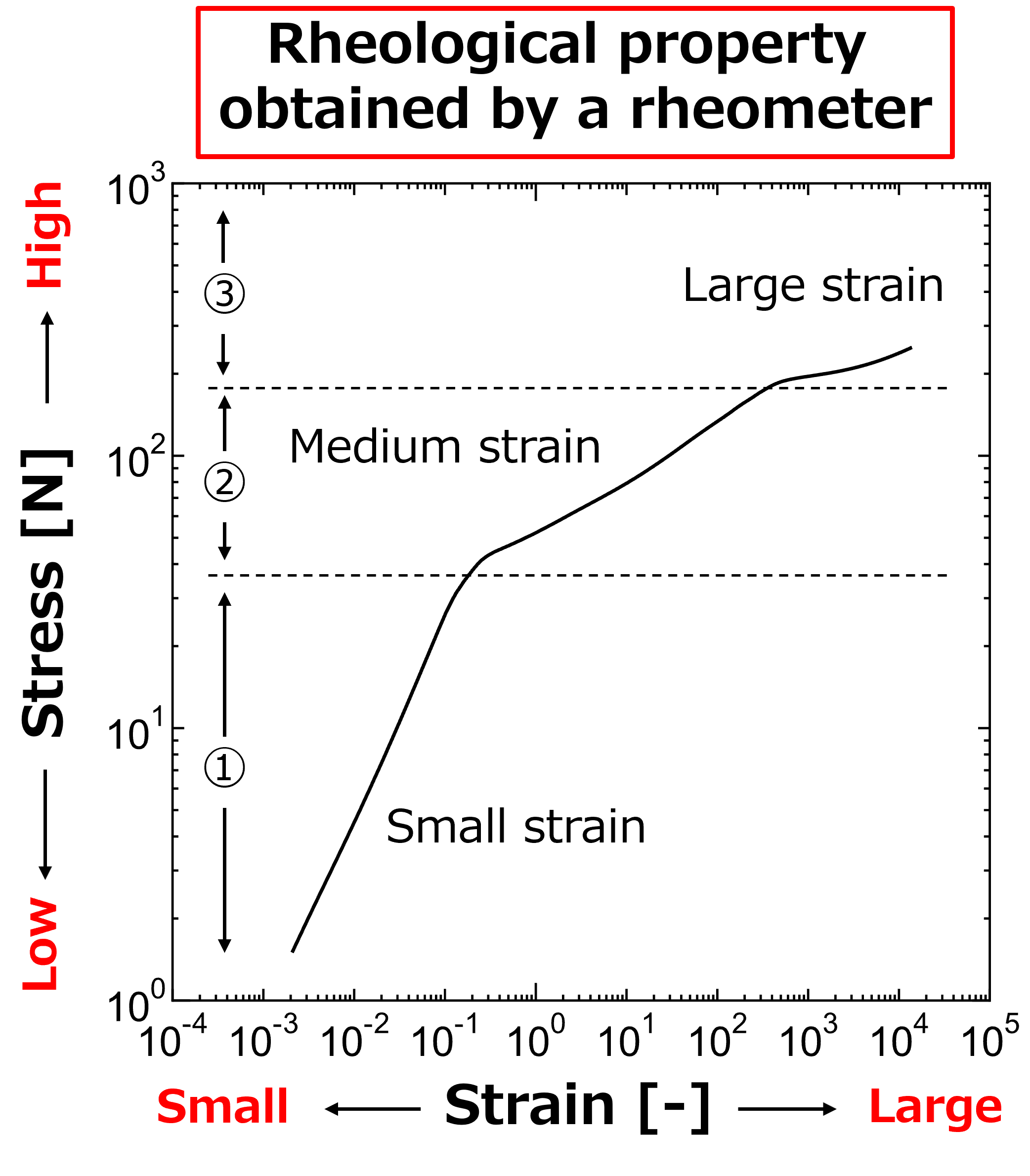

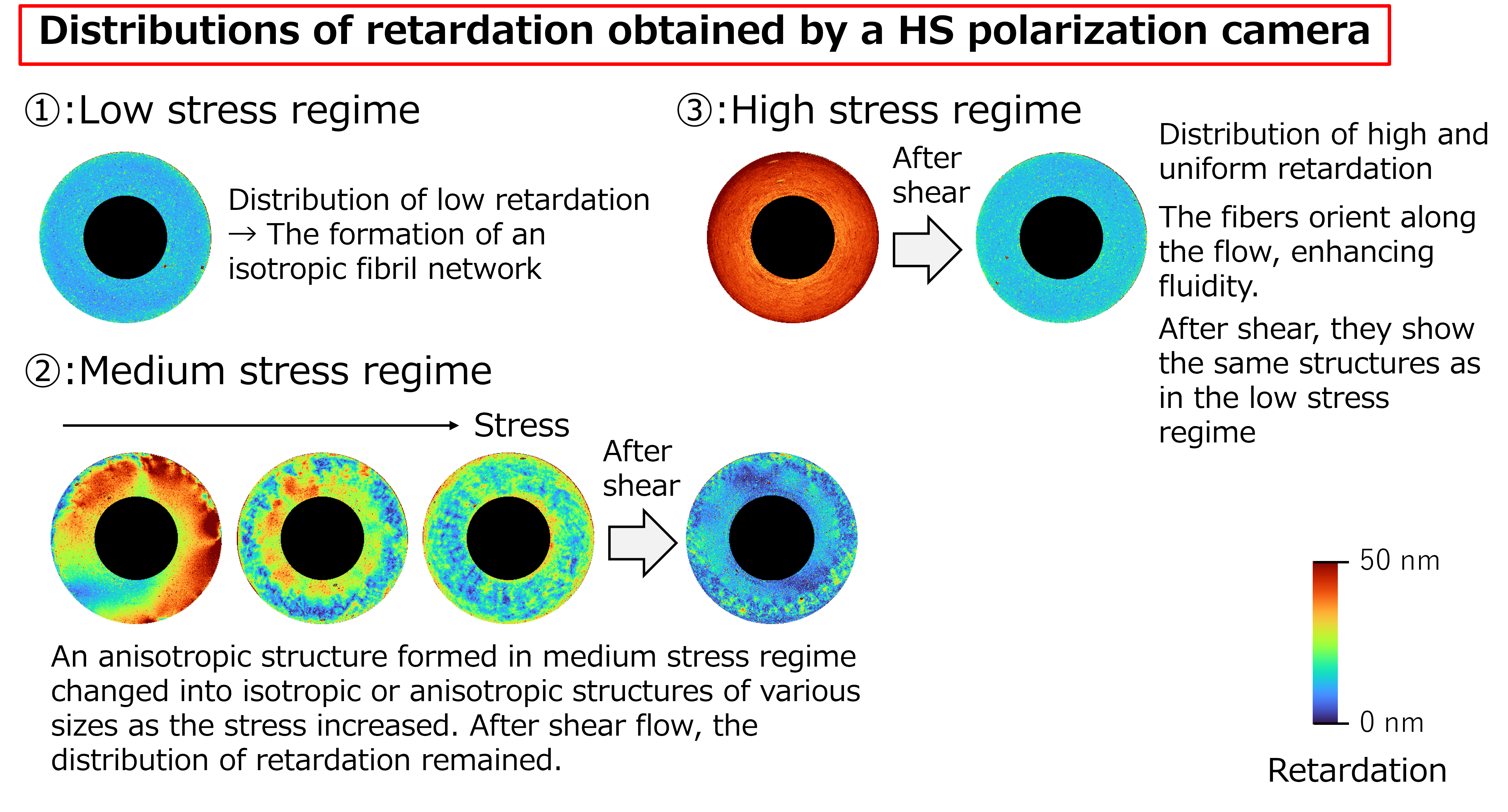

The following figure shows the relationship between the force (stress) applied by the rheometer to the CNF sample and the resulting deformation (strain). The characteristics of this relationship can be classified into three regimes: low stress, medium stress, and high stress. By using a high-speed polarization camera, it is possible to clearly observe the structural evolution of the CNF suspension.

- Low stress regime: an isotropic structure (fiber network)

- Medium stress regime: an aggregated structure resulting from fiber-to-fiber contact (with the aggregation size changing in response to stress)

- High stress regime: a homogeneous structure resulting from fiber orientation

These structural evolution reveals that functions such as shape retention and enhanced fluidity are being realized, making it possible to consider optimizing CNF materials according to development objectives. For example, in development that focuses on ease of deformation and flow rather than keeping shape, it is important to design in a way that prevents the formation of aggregation structures. Conversely, if the focus is on keeping shape, the design should aim to preserve these aggregation structures. In other words, it is essential to effectively control the formation or collapse of aggregation structures observed in the moderate shear regime.

For instance, when using CNF materials to control the properties of products like hand cream, they must be easily handled (such as being removed from the container or applied to a skin). In these situations, it is often sufficient for the material to keep its shape under the force of gravity. On the other hand, materials used in 3D printing (such as bio-3D printing with nanofibers) need to keep their shape under much larger forces.

For this purpose, it is necessary to investigate the following effects on the formation or breakdown of aggregation structures:

- Influences such as fiber length (aspect ratio) and the electrical properties of fiber surfaces

- Effects of fiber concentration

- Other aspects, including the relaxation time of structures when flow ceases

Even in these investigations, our developed measurement system proves to be powerful. This is because we can measure the prepared samples with the rheometer and observe structural evolution with the high-speed polarization camera simultaneously.

This time, we presented a case study on CNF suspensions. However, through measurements of various materials, we have found that this measurement system can also be applied to somewhat opaque materials such as cosmetics and gel materials. Furthermore, it has become clear that even if the properties measured by the rheometer show similar tendencies, structural evolution of the sample significantly depends on the material.

This measurement system, developed with the perspective of simultaneous evaluation of properties and structure, aims to contribute to the speedy and efficient development of new materials and optimization studies. We hope it will be instrumental in the development of new valuable functional materials.

Category

- #Polarization high-speed camera

- #High-speed Polarization Camera