Feature

We propose an infrared R&D measurement system based on the world’s highest class high-speed and high-sensitivity infrared camera technology. It is suitable for various new applications such as high-speed temperature measurement, CO2 gas visualization, or welding temperature analysis.

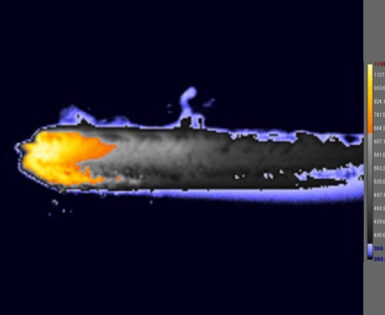

Laser Welding Visualization and Measurement

Visualization of CO2 gas

Visualization of momentary temperature changes

With our cooled infrared high-speed camera, thermal noise is reduced to the utmost limit by cooling the image sensor to -190°C, enabling high-precision, high-speed thermal imaging measurements, that have been difficult to achieve in the past.

This makes it possible to accurately measure high-speed phenomena, such as the temperature rise at the moment of breakage in a tensile test, the temperature rise of a workpiece during laser processing, or the temperature measurement of a high-speed moving object. Also, by detecting extremely small temperature changes with high precision, it is possible to evaluate, for example, the temperature rise of a semiconductor chip during operation or temperature irregularities in a liquid during temperature rise.

Visualization of CO2 gas

By visualizing invisible gases such as CO2, methane, ethane, ethanol, toluene, etc., one could detect and quantify leakages from pipes, exhalation flow, or characterize bare air flow using CO2; gas as an inexpensive tracer.

A particular concern when visualizing CO2 is that it is generally difficult to distinguish from water vapor.

On the other hand, CO2 cameras can discriminate gases by spectrally filtering infrared absorption at specific wavelengths.

In the 4.3 micron wavelength band, CO2 is much more absorptive than water vapor, so this concern can be overcome.