Feature

PA/WPA series systems provide high-speed birefringence measurement of transparent materials, such as transparent parts for residual stress evaluation, or transparent films for the evaluation of phase uniformity.

PA/WPA series

PA/WPA series systems provide high-speed birefringence measurement of transparent materials, such as transparent parts for residual stress evaluation, or transparent films for the evaluation of phase uniformity.

Ranging from microscopic to macroscopic (~50cm), the field of view adapts to any measurement situation, and there is a system for each size.

PA series measures birefringence and phase difference with a high resolution of 5 million pixels at high speed, for low phase difference with a measurement range of 0 to 130 nm.

Suitable for measurement of glassware and other low phase difference targets.

WPA series expands the measurement range of phase difference from 0 to 3,500 nm by measuring birefringence/phase difference distribution over three waves.

Suitable for measuring large transparent resin products.

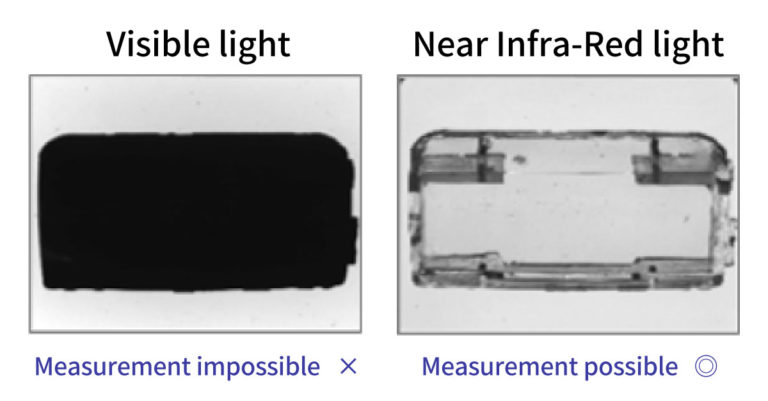

PA/WPA-NIR series

Operating at 850nm wavelength, this system provides strong tools for process and quality control of pieces not transparent at visible wavelengths, such as special resins and chacolgenide, used for example in LIDAR and face recognition systems.

VR lens evaluation system VRG-100

Dedicated equipment for evaluating VR-related parts

【Main specifications】

・Operating wavelength:466nm、543nm、650nm(Customization available)

・Retardation measurement range:0~λ/2(QWP measurement available)

・Measurement of retardation and circular polarization degree (ellipticity) for each RGB color is possible.

・Samples containing polarizers, which could not be measured with the conventional WPA series, can also be measured.

・Real-time measurement of the relative angle between the polarizer and the QWP is possible.

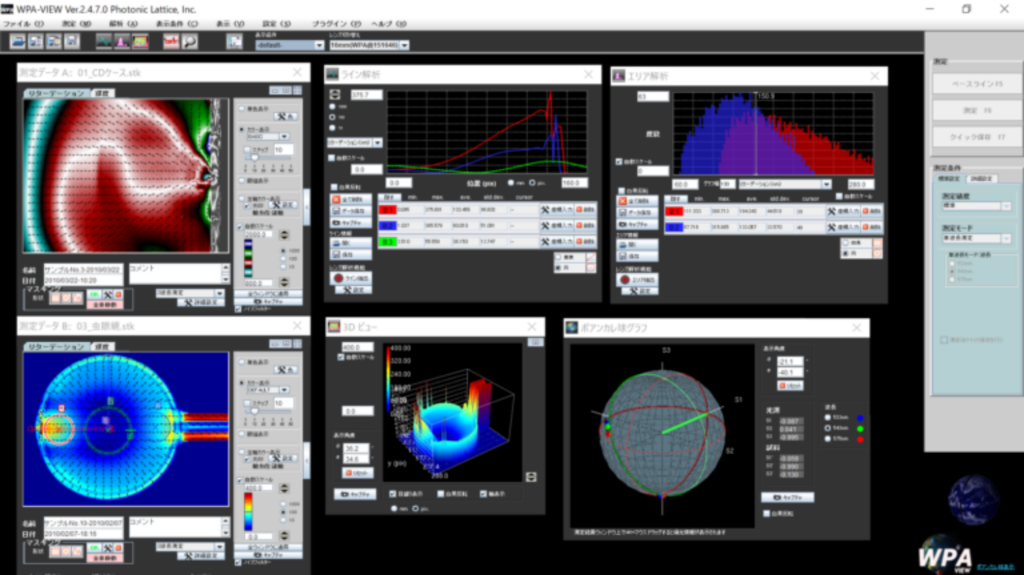

Multiple Display & Analysis Functions Dedicated software PA/WPA-View

Dedicated software PA-View & WPA-View provide many display and analysis functions to graph and compare multiple sets of data on a single screen.

Movie of basic operation of PA/WPA-View (in Japanese) *BGM will be played.

A broad range of optional functionalities

Options such as change of field of view size, increase of the measurement range for high-retardation samples and various software analysis functionalities are available to extend PA/WPA, satisfying your needs.

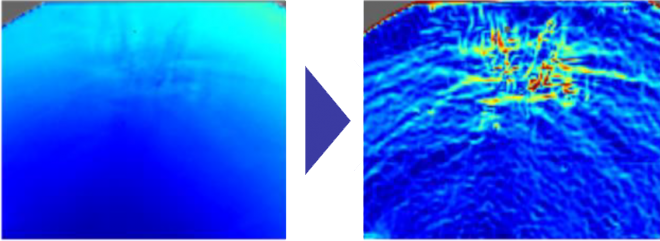

Data Processing Function

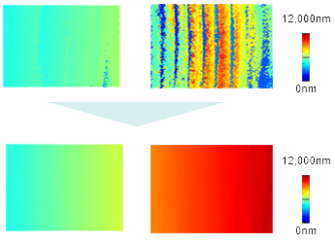

Various filters, such as noise reduction or local variations enhancement etc., are provided to help your data analysis tasks. Configurable and multiple filters can be applied simultaneously.

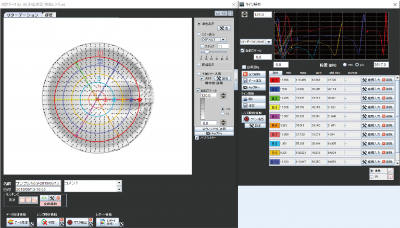

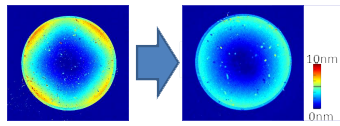

Lens Analysis Function

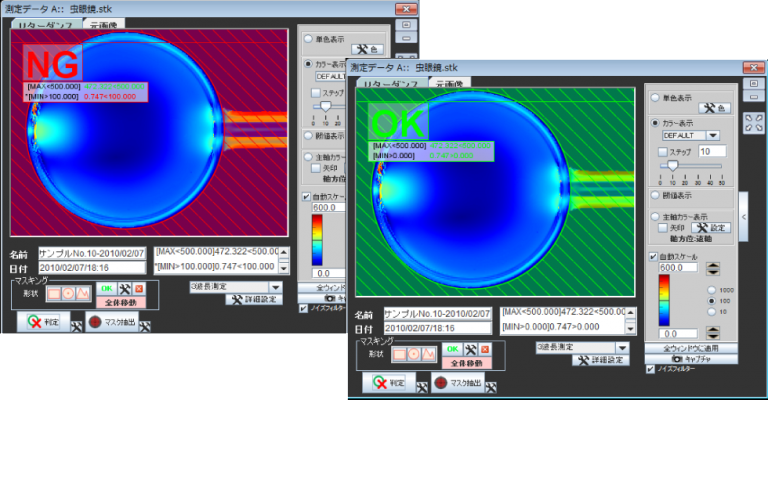

Automatic detection of circular lens followed with OK/NG detection, based on user-based criteria related to statistics on the retardation and axis orientation within the lens area.

Real-time Decision Function

Real-time OK/NG decisions using criteria inherited from the lens analysis function (see above) are available. The resulting conformity information for each piece is displayed in real-time, allowing use of this function for 100% inspection in high throughput environments such as manufacturing lines.

Real-time Analysis Function

Measurement time is virtually reduced to zero, as retardation information is displayed real-time at the camera refresh rate, and real-time refreshing of graphical functionalities allows getting statistical information at glance. This function is perfect for fast evaluation of pieces in high throughput environments, such as manufacturing lines.

High-Retardation Option

y changing the operating wavelengths, this option increases dramatically the measurement range of the WPA system, enabling evaluation of high-retardation materials.

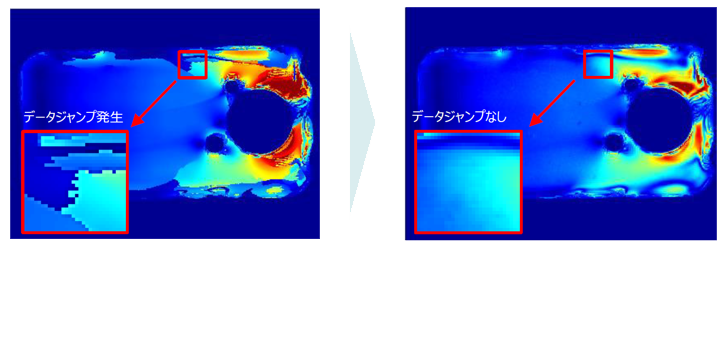

Chromatic Dispersion (CD) Mode

This option uses a different algorithm to evaluate retardation, by-passing the limitations which apply to samples that do not conform to a strict birefringence model (thick and/or complicated plastic molded parts, etc.), for which the standard algorithm tends to output erratic data.

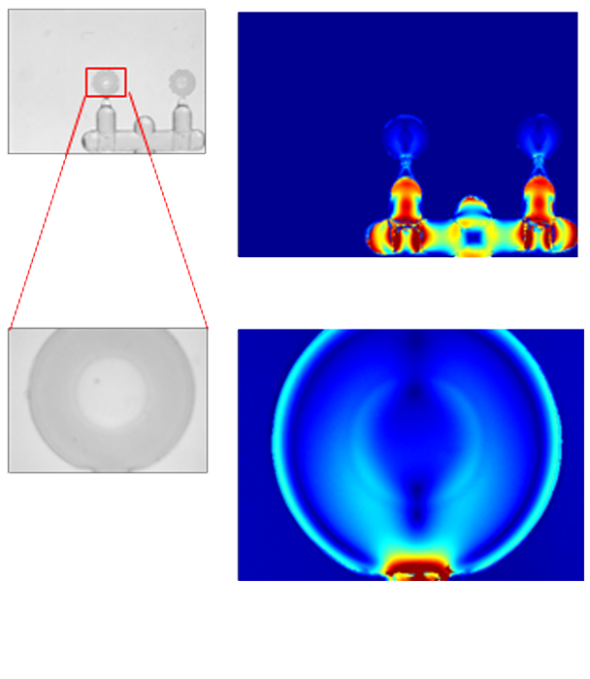

Zoom Lens

This is an optional lens allowing zooming into smaller object that is too big to be evaluated with a microscopic type system.

It is optimal for smaller objects or to zoom into small areas of bigger objects, in order to dig into their detailed structures.

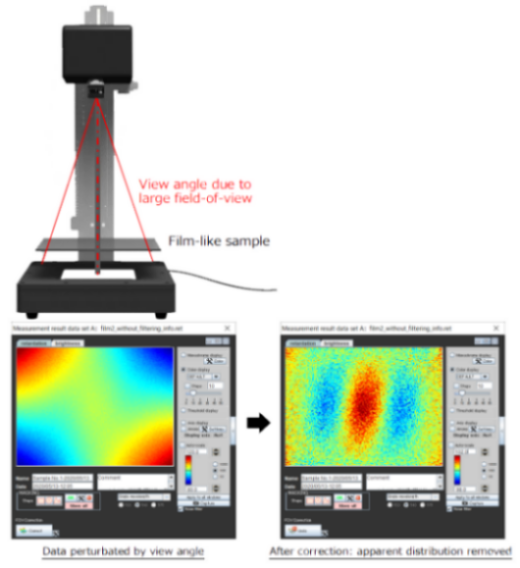

Field-Of-View (FOV) Correction Function

When measuring a large sample, the angle of view may affect the measured phase difference.

This option can remove the apparent phase difference due to the angle of view.

Lens Measurement Stage

The stage can be reduced the fixed retardation caused by the measuring instrument that occurs when measuring a lens with a low retardation.

Shading cover for PA/WPA

Light shade cover to prevent reflection of disturbance light.

Remote-Control Function

This is a software option to externally control the system, allowing to integrate the system into a larger manufacturing or testing infrastructure, for automated quality control.