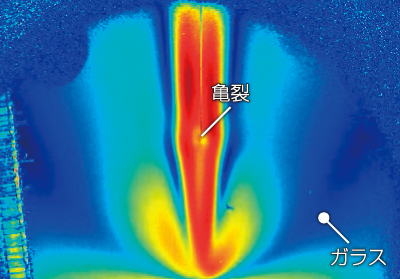

Evaluating the crack propagation process of glass

Real-time evaluation of broken glass cross-sections by high-speed polarization measurement.

Chiba University, CATs-lab (Chiba Advanced Technology and science Laboratory,) Professor, NOBORU MORITA, Professor, HIROFUMI HIDAI, Assistant professor, SOUTA MATSUSAKA

Glass substrates used in electronic devices are often cut into desired shapes by a fracturation method, and as devices become smaller and thinner, there is a high demand for improved quality of the fractured surface.

The morphology of broken glass fracture surface depends on the crack propagation behavior, which is determined by the internal stress field of the glass.

Therefore, if the internal stress field of glass at the time of crack propagation can be determined by polarimetry, it is possible to estimate the quality of the fracture surface before actually fracturing the glass.

CRYSTA can measure the phase difference of birefringence with high temporal resolution, which is very effective as a visualization method of the internal stress field of glass during the fracturing process.

We have proposed a method to estimate the fracture surface morphology in real time immediately after crack formation, based on the fact that the characteristics of the phase difference variation differ depending on the crack propagation behavior.

The high temporal resolution of CRYSTA will contribute to yield improvement in the glass substrate manufacturing and machining processes, because it enables immediate identification of fracture surface defects.

related product

Category

- #Birefringence & stress strain measurement solutions

- #Polarization high-speed camera

- #High-speed Polarization Camera