Tensile testing of transparent polymers

New Material Characterization Techniques Using Polarization and Infrared Cameras.

Measuring stress distribution and temperature irregularities in resin materials, glass, or high-performance films is one answer to this question. Those elements are among the most important factors to understand in order to control production processes of materials and products made of those materials.

When submitted to tensile testing, stress, temperature, and their non-uniformity are closely related to the non-uniformity of the mechanical properties of the material. For example, if the film thickness is uneven, temperature bias will appear on the film surface due to the difference in heat capacity caused by the difference in volume. Even if the thickness is uniform, if there is a spatial difference in the orientation state of polymers, we would be able to measure the change in orientation from the stress bias during deformation.

Therefore, if stress distribution and temperature irregularities can be measured, it will be possible to understand material properties in more detail. It is also possible to examine the validity of CAE and numerical analysis results from a previously unseen perspective.

Against this background, the University of Tokyo has started an experiment to observe the deformation state of materials during tensile testing using simultaneously a polarization camera and an infrared camera, both from our products.

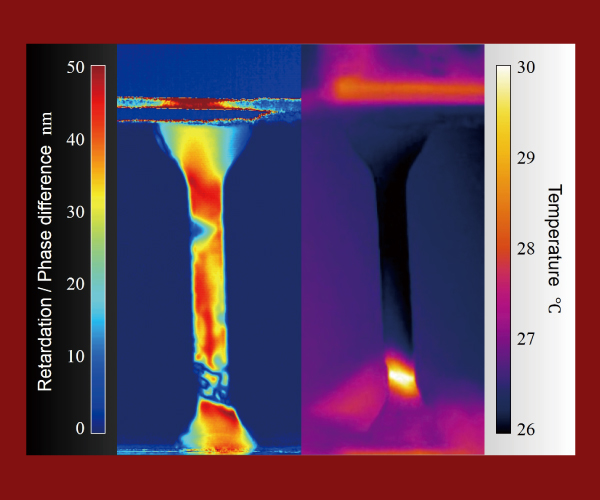

The movie above shows the results of a tensile test of a transparent resin material, simultaneously captured by a polarized high-speed camera (left) and a high-sensitivity infrared camera (right) to measure new material properties.

Polarization high-speed camera CRYSTA

High-speed imaging of stress distribution, molecular orientation, and residual stress occurring inside transparent material.

High-speed, high-sensitivity infrared camera

High sensitivity imaging of temperature distribution on the material surface. Visualization of strain (energy) is also possible.

The polarized light observation result on the left side shows the internal stress in a transparent resin sample, using pseudo-colors. The stress throughout the material becomes stronger (red) as the load increases, and when necking occurs, the stress distribution becomes non-uniform.

The infrared observation on the right side shows the surface temperature. It can be seen that the temperature rises sharply at the moment necking occurs, and the area with large surface strain emerges due to the temperature rise, and its position gradually moves upward.

As in this experimental setup using a combination of different measurement devices, we can offer a new approach to elucidate material properties that could not be predicted by conventional methods

related product

Category

- #High-speed heat propagation imaging solutions

- #Birefringence & stress strain measurement solutions

- #Polarization High-Speed Camera

- #Infrared High-Speed Camera

- #High-speed infrared camera

- #Internal stress