Introduction of Lens Measuring Stage, effective for birefringence measurement of lenses

Reducing measurement artifacts in lens birefringence evaluation

For special cases of lenses with low birefringence and high curvature, a recurring problem was happening with some of our customers handling such lenses. This problem takes the form of a fixed pattern that occurs in perpendicular direction in the outer ring part of the lens.

This measurement artifact, not characterizing the properties of the object (the lens), is caused by the bending of light rays through the lens. This problem, not specific to Photonic Lattice, Inc. systems, is in fact common to all similar camera-based systems, using the same measurement principle.

We have developed for our customers facing this issue a method to reduce this pattern, as a new hardware option for our PA/WPA systems, called “Lens Measurement Stage.”

This product is useful for those who need to evaluate low-retardation, high-curvature lenses, especially glass lenses.

What kind of artifact?

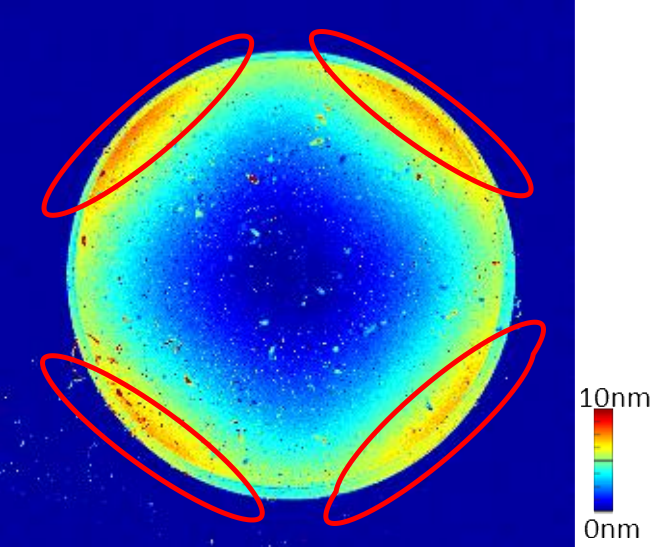

When measuring low-retardation, high-curvature glass lenses, a fixed pattern, is observed in the red circled areas in the image below. This artifact occurs as well in lenses with no intrinsic retardation at all.

This effect, which is due to the geometry of the object (the lens), is common to all measurement systems using the same principle.

Example of artifact reduction with our new “Lens Measurement Stage” option

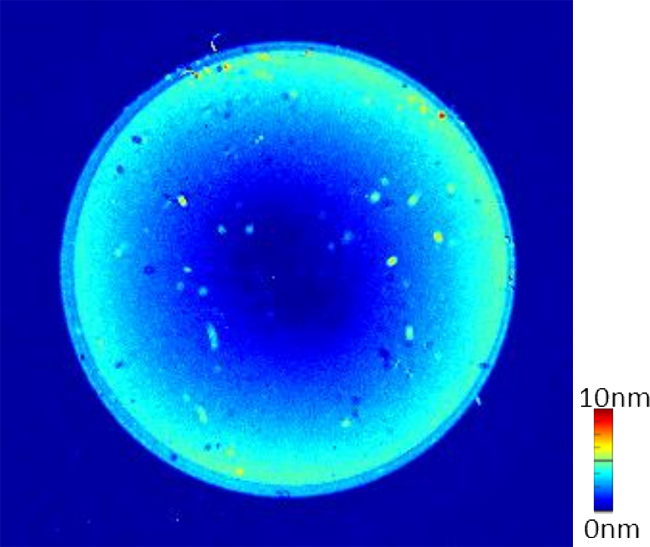

Using our new “Lens Measurement Stage” option with one of our PA/WPA series systems, the fixed pattern due to lens geometry is significantly reduced, as shown in the image below. The evaluation of small variation of actual birefringence inside the object is now possible.

Since this option is based on specific hardware implementation and not on additional data processing, you can benefit from the artifact reduction feature of this option without losing one of the main features of our systems: namely high-speed measurement.

Video demonstration with details (language: Japanese)

The video explains in detail the causes of measurement artifacts when measuring low-retardation, high-curvature lenses, and how they are reduced by the new “Lens Measurement Stage” option for PA/WPA.

※Caution: background music will be played, so please pay attention to the volume.

Please not that the reduction effect on measurement artifact depends on the sample.

To be sure that the effect is sufficient for your evaluation needs, please feel free to contact us, and send samples for demo measurement (free of charge).

Category

- #2-D Birefringence Measurement System

- #Birefringence & stress strain measurement solutions

- #2-D Birefringence Measurement System

- #Birefringence Measurement System