In-line/off-line mapping-type birefringence measurement system

KAMAKIRI MEM-LS

Partial inspection and evaluation on prototype line

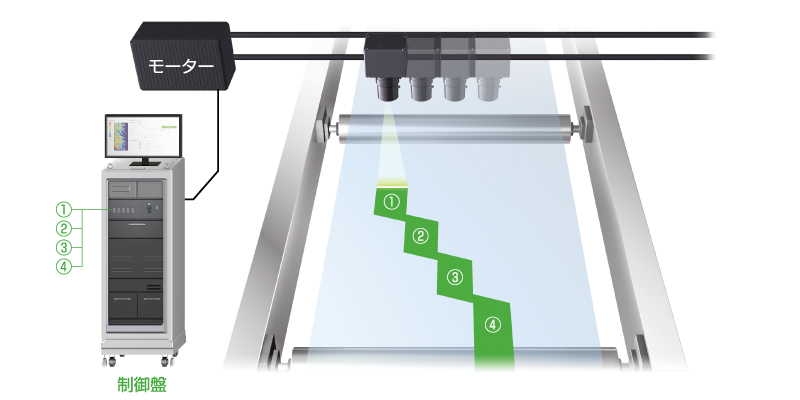

KAMAKIRI MEM-LS can measure and inspect the part of the line you want to see with one camera and the part in the width direction of the film in-line, just like a sampling inspection.

As a result, the sampling inspection time is shortened, the production of defective products can be stopped quickly, and the yield can be expected to increase.

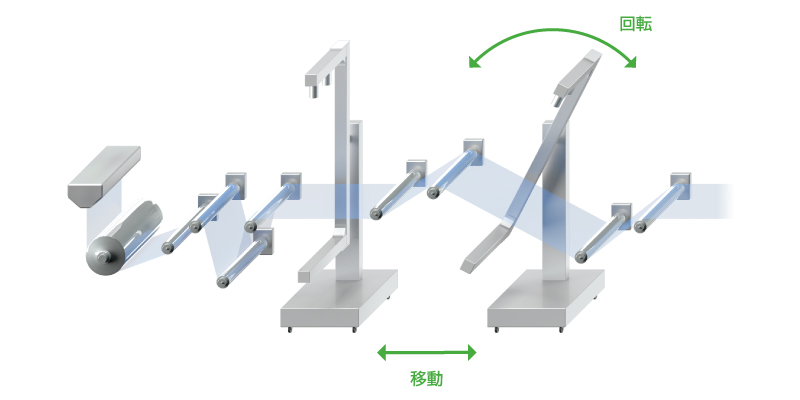

Allow to customize and provide installation jigs according to the situation of the production line.

In addition, if there is a need to fix the device or measure the full width, it is possible to update and modify KAMAKIRI STS-LS.

Feature

01

Start-up and adjustment assistance for multiple lines with a single unit

Partial inspection at a focused position

Moving type for installation in accordance with the line

Traverse type that can measure any point

02

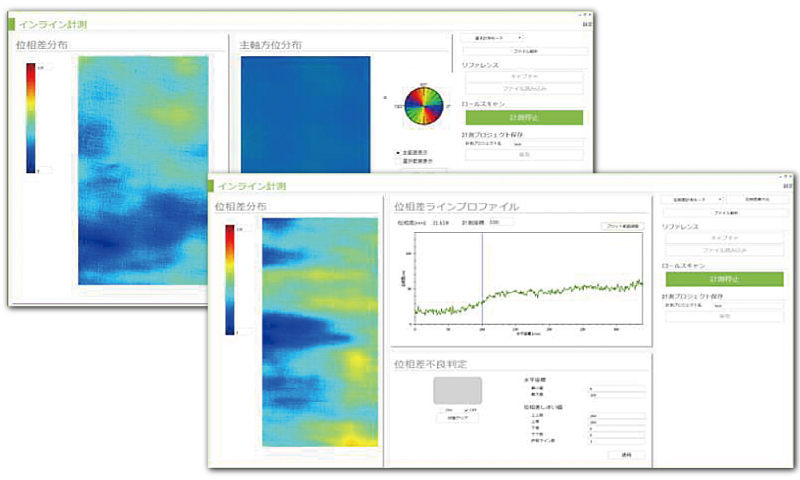

Functions specialized for partial inspection

System configuration suitable for continuous inspection for about 1 hour

- Retardation & main axis orientation display

- Distribution updated real-time

- Line profile along transversal direction

- OK/NG decision

- Available after saving data

- [Analysis Elements]

- Stats (max, min, ave, stdev)

- Line profile along transversal direction

- Line profile along conveyor direction

| Model name |

|

|---|---|

| Major application |

|

| System Features |

|

| measurement item |

|

| Retardation measurement range |

|

| Retardation repeatability |

|

| Principal axis orientation measurement range |

|

| Principal axis orientation repeatability |

|

| Center wavelength for measurement |

|

| Number of measurement points |

|

| Maximum measurement width at line scan |

|

| Supported transport speed |

|

| Software [Japanese/English] |

|

| Customization achievement |

|

Catalog & Company brochure Download

Category

- #Full-length, full-width film quality control solutions

- #In-line/off-line mapping-type birefringence measurement system

- #Birefringence Measurement System