Film is entering the era of full surface warranty Preventing the outflow of defective products with “Birefringence imaging”.

Are you having trouble with the full surface warranty on your film?

As displays become larger, thinner film, and higher in resolution, the quality requirements for optical film base materials and stretched films are increasing.

We have been selling desktop type birefringence imaging equipment for research and development and sampling inspection, but in response to the need for inline full-surface inspection, we began selling the inline KAMAKIRI series for mass production lines in 2016.

Therefore, this time we will introduce our approach to full-surface warranty based on measurement examples with the inline type KAMAKIRI series!

Approach to full-surface warranty

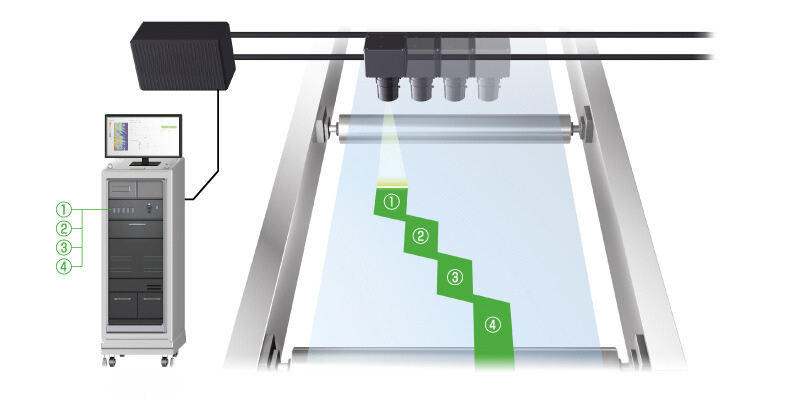

KAMAKIRI STS-LS for mass production lines

https://www.photonic-lattice.com/products/kamakiri-sts-ls/

KAMAKIRI STS-LS is the only one in the KAMAKIRI series that can connect images from multiple cameras and display the full width birefringence image of the film on one screen.

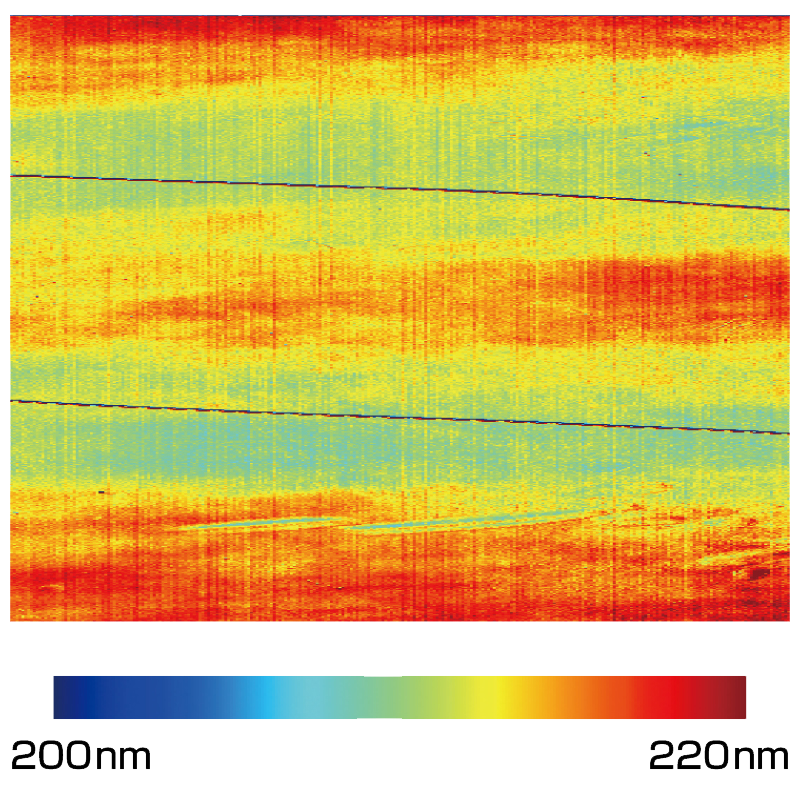

In addition to the graph display like a conventional retardation meter, the measured image of retardation or principal axis orientation is displayed and updated live.

On-site, this live image allows you to check periodic transverse waves, diagonal streaks, and continuous spot irregularity that suddenly occur, allowing you to quickly detect defects and take steps to improve the production line.

Example of measurement

It is used to evaluate and inspect the optical distribution and irregularities of orientation of

transparent optical films (PVA,COC,COP,TAC,PC,PET,PMMA,PI).

https://www.photonic-lattice.com/case/case-811/

New feature:Live sampling function

Recently, there has been a desire to output data forms for full-surface warranty, and a new function “Live sampling function” has been added from September 2022.

The “Live sampling function" is a function that outputs data measured at regular time intervals to a CSV file in response to the need to store and operate KAMAKIRI data on their own servers in response to the trend of DX in factories.

This increases the degree of freedom in statistical analysis of full-surface data and the creation of management data, supporting operations aimed at achieving full-surface guarantees.

Category

- #Full-length, full-width film quality control solutions

- #In-line/off-line mapping-type birefringence measurement system